On the Job: A Week In The Life Of a Recipe Developer + Consultant

it's not all about the recipe when it comes to consulting for a bakery

hello hello!

I’m just now getting back from two weeks in Los Angeles, trying to survive the insane heat while simultaneously trying to maximize the efficiency of a pastry program built around temp control. So, you know, having a grand ole time.

For the most part I try to keep my IRL work life separate from my internet work life. Mostly, because the work I do sometimes involves an NDA so I’m contractually obligated not to talk about it. But, also, for my sanity and for reasons we will get into a little later on. This time around though, I’m back working with my friends at Out of Thin Air, which you couldn’t pay me enough to not talk about. While no kitchen is perfect, the team at OTA is great and I’m a really big fan of everything they produce. I’m really grateful to be able to work with such an amazing, talented and SMART team.

If you’ve been around for a while you’ll remember last year we set out to develop a whole grain pastry program. It was a project that started off in the middle of January 2024 and was not completed until the end of June 2024. 90% of which was developing our ideal base croissant dough. By far the longest I’ve ever worked on a single recipe. You have to consider though, the croissants, at least any croissant worth eating, are a minimum 3 day process. So, day one: mix the dough + bulk ferment in the fridge overnight. Day two: Laminate the butter into the dough + cut and shape croissants. Day three: proof, egg wash + bake off croissants. That’s 3 days before we see the results of our work to decide what needs to happen/change for the next test. These changes were anything from, upping the hydration of the dough, lowering the amount of yeast, dialing in the right mix times in each sized mixer we had at the time, which folds to perform and how many, how long and where the bulk ferment should happen, the butter to dough ratio, what time to pull croissants to proof. It’s a painful game of waiting and watching— the longest 6 months of my life. Until one day we got it, and we got it again and again and again. Getting it right once is “easy”, but getting it right consistently is what makes a recipe a good one.

Along the way there were plenty of solid croissants. Plenty of croissants we were proud of. But, the variables of the kitchen often made results hard to replicate. Not every kitchen is the same, the recipe and procedure we use here isn’t cookie cutter going to fit into the flow of another bakery or even the home kitchen.

Someone asked me though while I was here working, what my favorite croissant in LA was. I had to stop and think about it for a while, and with all eyes on me, Kevin asks, “It isn’t you know, this one? It is your croissant.” That’s the thing about consulting and developing for a client rather than just for myself/ the internet. Like sure, that is my croissant, my previous knowledge, training and extensive hours of research and testing that made it. But, it’s not my croissant. Yeah, Alex gave me tons of free reign and creative freedom but at the end of the day it’s his program, his business and his call on what the final croissant is. Do not get me wrong, this is a very good croissant, it’s my ideal croissant for what it is but, but, I don’t think I can call it my favorite. That’s just me being #real.

My work as a consultant isn’t just developing recipes though. In the early days of the Out of Thin Air pastry program, it was equally setting up the kitchen. For what you want to produce you’ll need this equipment, you’ll need to order from these vendors, for efficiency sake this should be stored here and not over here. Then halfway through the project Alex moved from two small kitchens in a commissary space to a 4,000 sqft bakery across town. So things changed and we had to reconfigure the set up to make sense in this new space— the fridge should be in the hallway and the freezer should be in the pastry room, because the team will need to reach in there more often than into the fridge. All the pastry dry goods should actually be stored across the building over by where they’ll prep fillings rather than in the pastry room.

The reason I came back, was not to develop anything new. Alex brought me back because in less than a year he and the team have grown the pastry program (bread too, I GUESS) to having 46 wholesale accounts. Mind you, a year ago TODAY we were still fighting for our lives to have consistent product. We were baking off maybe 75 pastries for the Atwater Farmer’s Market once a week. Now they’re baking off four to six racks of pastries (≈1000 pieces) per day. Now, some of the things we were doing a year ago just don’t make sense. So, I came back to help make things time + labor efficient.

My number one objective for this project was to size the croissant plaques up to be twice as big— two times the amount of croissants laminated in half the time. Which maybe sounds like a no brainer, just make everything twice as big and twice as long. In theory sure, but, when we first started we made the decision to use butter that already came in sheets to cut out having to temper and shape butter for lamination. We would sheet the dough out to size, throw it back in the freezer for 30-45 minutes while the butter sheets came to temp. Ideally we were looking for the dough to be around 36-40F and the butter to be 50-55F before we locked in the butter and preformed our two folds back to back. But, now with bigger plaques/books that it’s possible. The dough is too long to throw back onto a sheet pan to chill down to meet the butter.

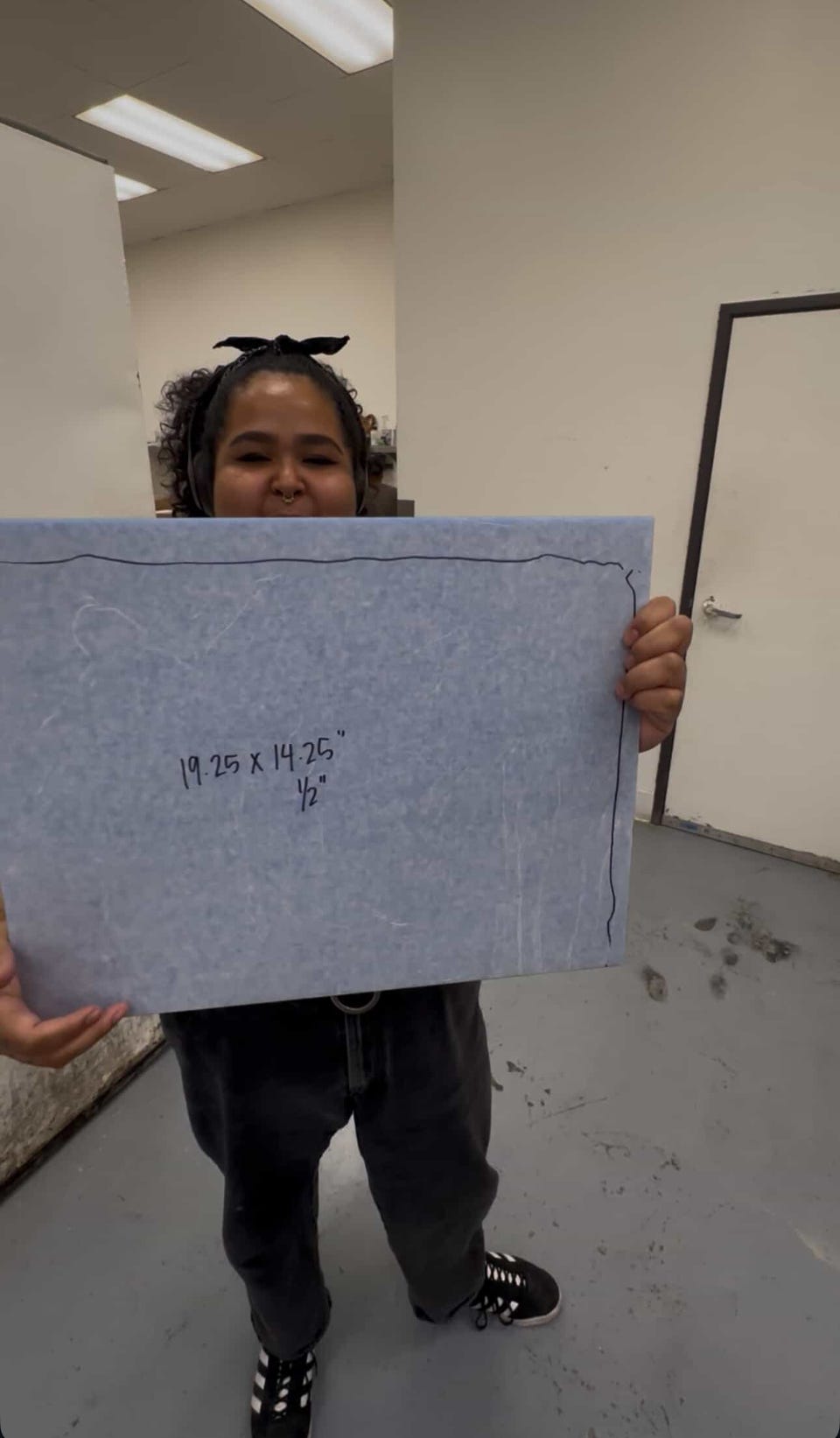

The preformed butter blocks are 12”x12” so to double up we would have to make 24”x24” butter blocks, but another thing to consider is the equipment you have. The belt of the sheeter is yes, 24” wide, but in practice comfortably fits dough that is 23” wide without getting caught on the sides and tearing as it passes through. So, we have to play around with switching the dimensions of the butter. Which involved getting custom butter molds made, which I’m not pointing any fingers (literally, my fault) but, we had to get 3 prototypes made to actually get it to the right dimensions.

Then there’s addressing the other pain points of a rapidly growing team + program. When I wasn’t working on the plaques themselves, I was doing a lot of observing. Watching how the team preps things, asking them what they’re doing and why. After that, I give Alex my very professional opinion- 86 about 1/3 of the current menu because it doesn’t make any sense from a labor perspective to have 2 people spending 4 hours straining spinach for the spinach and feta filling. Get rid of the monkey bread that you make ONCE A WEEK because it’s taking 3 people at least 3 hours to prep the whole thing- at the very least switch up the shape to be more, you guessed it efficient. But, you know, that’s the thing not in my control, because at the end of the day he doesn’t want to get rid of any of the things that made this program a success. Which, I get, and like I said it’s just my two cents as a consultant. If he wants to take the advice he will… in his own time. A lot of these items were from a time when yeah, we were making small batches. But, a 1x batch of a filling turned into a 42x batch, 2 times a week really quick. Somethings just weren’t meant to scale.

Which brings me to another point in this, at the end of the day, a lot of what I say is just that, my two cents. It’s up to the business owner to decide if they actually want to take what I change/suggest and apply it to their business. It’s also the job of the team to uphold the standards we put in place. Which is another reason why I don’t share a lot of this work that I do. I don’t want my name tied to a program if at the end of the day they can’t maintain quality standards. If a few months down the line they start producing *shit*. Because, I’m not their chef, I come in and do my part. It’s up to them to QC and make consistent product.

I don’t think hiring a consultant is worth it if you don’t have a team that cares. There have been 3 times where I fully had to turn down a job because owners have reached out wanted to revamp their menus to make them more enticing to their customers. But, when I went in for the initial consult to see what they *actually* need I found teams of people hired just to fill the space. None of them were properly trained and none of them really cared to do the work. I can develop a great recipe for ya, but a recipe doesn’t change the skill level and ability or the drive of your team. I could give you perfect flawless recipes but, if they people making them aren’t also perfect and flawless, the recipes will fall on their face. They aren’t a magic cure all for lacking technique. Standardizing procedure isn’t gonna fix a team that doesn’t care to follow it.

I go into most jobs pretty open, with no concrete plan, rather just laser focused in on the final objective. It’s never gonna be day one we do this, this will happen day 2 and by day 5 we will have done it. So this is what my two weeks at OTA looked like:

Day 1

Start with some test plaques. They’re twice as big now so play around with different butter block dimensions.

Write down all dough and butter dimensions for following days

I noticed the dough the way it was being shaped for bulking was struggling to go through the sheeter since it proofs twice as high now. So, work with the bread team (who mixes the dough) to change the shape/method they use for shaping the croissant dough for bulking and overnight proof.

Shatter a butter block in the dough- because well it had been a year since I’ve laminated and the dough wasn’t cold enough, something I’ll address in the coming days. But, we trudge on with a shattered block because, at that point it’s glorified rough puff and will still get you a beautiful crumb, you just gotta use a little more finesse.

Chat with the team about what they’re working on, how the feel about the work they’re doing. Ask what bits are a time suck/bottle neck for them.

Tray up test bakes from today’s croissants

Days 2-3:

Crumb check + taste test yesterday’s croissants. Try the cookies and other pastries while we’re at it. Notice some inconsistencies in the cookies, make a note to touch back with the team on proper mixing and dough tempering.

Decide on final butter block dimensions and dial in proper dimensions for the plaques/books at every step in the process. For lock-in dough should be x inches by x inches. Dough should be x inches wide for the first fold. Dough should chill to x degree before throwing in the second fold.

Test different fold sequences, two book folds (current standard) vs one book + one letter fold (less layers, but airy final product)

Make sure that after the second fold the plaques are 15” or less in width for final shaping purposes.

Tray up some of the test product for side by side comparisons.

Chat with Kongruent works to have custom butter molds made to chosen dimensions.

First Charlies’s fixtures run to get the team everything they need. Alex won’t spend money on his own business- but, I will buy everything and anything that makes everyone’s lives easier. You need more cambros? got you. You want a 7 wheel bicycle cutter? Yeah okay. I want a 16 capcity hot dog roller with bun warmer for “family meal”? That’s a stretch but, I’ll get him next time.

Day 4:

Have the team try the croissants with the different folds and get feedback on which fold combo they prefer. Use that to decide what to move forward with.

Full switch to implementing double plaques at this point. Start training pastry team on proper temp, timing and dimensions.

Most plaques will still be the double book fold while we test the book letter fold against the rest of the shapes. Does it work for choc, ham and danishes? Before we move forward with switch the folds over.

Circle back on the cookies and brush up on proper mixing technique in the XXXL mixer. Because timing changes when you go from making 90 cookies at once to 435 at once.

Day 5:

Decide the book letter is best for the croissants across the board. Implement a full switch to the new fold combo.

Oversee pastry on lamination. Troubleshoot butter shattering— dough is too warm and butter too cold causing the butter to crack. Dial in new temps for both dough and butter.

Work with bread team on timing for bulking the dough. Work with them to figuring out timing in the Am to ensure the dough is at proper working temp for the pastry team to start lamination.

Days 6/7:

More of the same. Timing timing timing.

Day 8:

A DAY OFF? Santa Monica Farmer’s market + a trip to Layla bagel- my former Wednesday routine <333

Day 9:

Cover for lamination. I worked a full lam shift for the first time in a long time. But, getting fully immersed in the flow is also important to understanding if these new plaques are actually time efficient. Gotta see if the juice is worth the squeeze. I was able to complete what would normally be about 7 hours of work in 4. What normally would have been 16 books was 8. So… I mean.

Big check-in with Alex on where things are, what things should stay, what should go.

Day 10:

The croissants came out mmmmm, off. Too soft and bready, so I have to chat with the team on what they’ve been doing. Work to figure out what went wrong and what needs to change. Test bake previous days products to see if it’s a singular event or if everything is going to come out like this.

Cross test shaping methods to see if that played a roll in the thinning of the layers

Find that it’s an isolated event and a result of butter getting too warm in the final sheet out and essentially incorporating into the dough.

Days 11/12:

Looking for consistency.

Really just a bunch of hands off stuff on my end.

One of these days I was supposed to help with the workload but got roped in to errands and a few other projects. Like, changing the shape of the monkey bread, etc etc. So, Harper ended up doing 14 books by themselves. Which inadvertently becomes a test to see how much the work load can increase on one person before needing a second shift to come in a help with shaping.

Day 13 *the final day*:

Update recipe cards to reflect the larger batch sizes the team is using. Instead of 1x, 2x and 3x, recipes are batched in a way that what used to be an 8x is the new 1x batch of a recipe.

Update the SOP for croissant dough lamination, including all the dimensions, thicknesses and ideal working temps.

Make sure everyone feels confident in the new plaques. Address any questions, comments and concerns.

Day 15…

Wake up to the group chat going off with issues with the proof, the bake off, and more <33333 love when problems arise when I’m 110 miles away <3333. But, as with any of these jobs my work is not done the second I step off property. I do offer up to 2 months of constant contact + revisions afterwards. Because, as is life in the kitchen- shit will hit the fan, something will go wrong after I’m gone. So, I’ll coach the team through what’s going wrong and we can brainstorm was to address the issues.

I was going to include a Q&A here about my work as a recipe developer + consultant, but this is kinda long… Ive already hi-jacked you for 13 minutes for this read. So they Q&A will be a separate post, so if any questions arose for you whilst reading, drop them in the comments!!

Chat soon ♡